How to Optimize Supply Chain Management System for Maximum Flexibility

In today’s rapidly evolving business landscape, supply chain flexibility has become paramount. The ability to adapt to unforeseen disruptions, changing market demands, and emerging opportunities is crucial for long-term success.

By optimizing supply chain systems, businesses can enhance their resilience, improve customer satisfaction, and gain a competitive edge. This article explores key strategies to achieve maximum flexibility in supply chain management.

Enhance Supply Chain Visibility

Optimize Supply Chain Management System

Real-time data analytics: Implement advanced analytics tools to gain real-time visibility into inventory levels, transportation routes, and supplier performance. This data-driven approach enables proactive decision-making and early identification of potential bottlenecks.

Advanced tracking technologies: Utilize technologies such as RFID, GPS, and IoT sensors to track assets and shipments in real-time. This provides granular visibility into the supply chain, allowing for efficient monitoring and management.

Collaborative planning, forecasting, and replenishment (CPFR): Foster collaboration with suppliers and customers through CPFR initiatives. By sharing demand forecasts and inventory data, businesses can optimize production planning, reduce lead times, and improve supply chain responsiveness.

Build Resilient Supply Networks :

Supplier diversification: Diversify your supplier base to reduce reliance on a single source and mitigate risks associated with disruptions. This strategy ensures a more robust and resilient supply chain.

Risk assessment and mitigation: Conduct regular risk assessments to identify potential vulnerabilities in the supply chain. Implement mitigation strategies, such as contingency planning and backup suppliers, to minimize the impact of disruptions.

Nearshoring and reshoring: Consider nearshoring or reshoring production facilities to reduce transportation distances and improve supply chain responsiveness. This can also help mitigate risks associated with geopolitical instability and trade barriers.

Foster Agility and Adaptability :

Modular supply chain design: Design a modular supply chain that can be easily adapted to changing market conditions. This involves creating flexible production facilities and leveraging modular transportation networks.

Scenario planning: Develop various scenarios to anticipate potential future events, such as economic downturns, natural disasters, or technological advancements. This enables businesses to prepare contingency plans and adapt their supply chains accordingly.

Digital transformation: Embrace digital technologies to enhance supply chain agility. This includes leveraging automation, artificial intelligence, and machine learning to optimize processes, improve decision-making, and enable real-time adjustments.

Strategic Partnerships in Supply Chain Management System

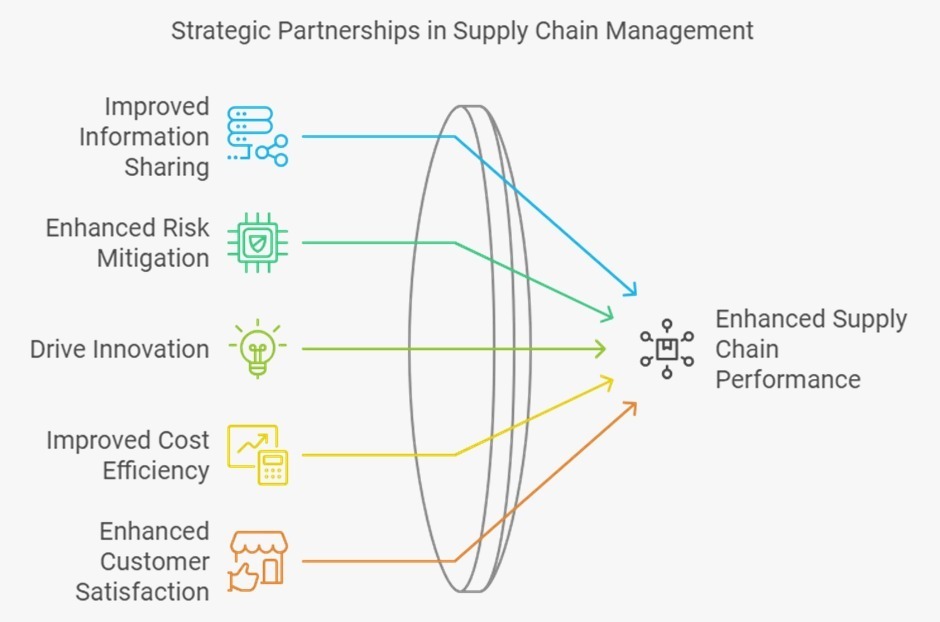

Strategic partnerships are collaborative relationships between businesses and their suppliers, forged on a foundation of trust, mutual respect, and shared objectives. These partnerships extend beyond transactional exchanges, encompassing a deeper level of cooperation and alignment that benefits both parties.

In the context of supply chain management, strategic partnerships play a pivotal role in enhancing efficiency, resilience, and responsiveness. By fostering a collaborative environment, businesses can:

Improve information sharing: Strategic partners can share real-time data and insights, enabling better demand forecasting, inventory management, and production planning. This enhanced visibility and transparency lead to improved decision-making and reduced risks.

Enhance risk mitigation: Collaborative partnerships can help identify and mitigate potential risks within the supply chain. By sharing information about disruptions, such as natural disasters, economic downturns, or geopolitical events, businesses can develop contingency plans and explore alternative sourcing options.

Drive innovation: Strategic partnerships can foster innovation by encouraging joint research and development efforts. By combining their expertise and resources, businesses can develop new products, processes, or technologies that enhance their competitive advantage.

Improve cost efficiency: Strategic partnerships can lead to cost savings through economies of scale, shared infrastructure, and optimized logistics. By working together, businesses can reduce transportation costs, negotiate better terms with suppliers, and streamline operations.

Enhance customer satisfaction: By aligning their goals and strategies, strategic partners can deliver better products and services to customers. This can lead to increased customer satisfaction, loyalty, and market share.

Developing strategic partnerships requires a deliberate and ongoing effort. Businesses should focus on building relationships with suppliers who share their values and long-term goals. Open communication, trust-building, and a commitment to mutual benefit are essential elements of successful partnerships.

Conclusion :

Optimizing supply chain systems for maximum flexibility is essential for businesses to thrive in today’s dynamic market. By implementing the strategies outlined in this article, organizations can enhance their resilience, improve customer satisfaction, and gain a competitive advantage.

Businesses can create a flexible and efficient supply chain that supports long-term success by focusing on supply chain visibility, building resilient networks, fostering agility and adaptability, and cultivating strong supplier relationships. Ready to Transform Your Supply Chain? 7th Mile Shift is Your Solution.

Read Also: Inventory Management a Comprehensive Guide

Tags : project management, raw material, logistical, continuous improvement, inefficiency, cost reduction, delivery time, on-time delivery, on-time, Supply chain management process, logistics management, supply chain operations, logistics management system, logistics system, different supply chain, transportation management, supply chain model, operations management, management software, supply chain performance, effective supply chain, supply chain processes, flow of goods, reduce costs, supply and demand, simple design, successful supply, logistics and distribution, meet customer, designing the supply chain, comprehensive supply chain, warehouse management, existing supply chain, supply chain partners, strategic design, overall supply chain performance, order management software, software development, company must, part of supply, supply chain involves, management of the supply chain, responsive supply chains, relevant information, risks in the supply chain, make your supply chain, customer demands, optimal supply, design process, operational efficiency, informed decisions, supply chain resilience, raw materials and finished goods, perfect supply chain, goods and services, design decisions, current supply, must be made, play an integral role, strategic decisions, efficient flow of goods, well thought and well explained, thought and well explained computer, well explained computer science, save costs, finished goods to reach, improve delivery time and reduce, flexibility in inventory capacity, come with better visibility, adjustments to overcome disruptions, play a crucial role, robust network, specialized software, careful planning, selection must be made, flow of goods and services.