Warehouse Design for Better Supply Chain Efficiency

If Your Warehouse Is Unable To Keep Up With The Demand Are you losing time and money due to delays and inefficiencies? An optimized warehouse design is more than just a storeroom: it can speed up your entire supply chain, increasing efficiency, productivity, and customer satisfaction levels.

Principles For An Effective Warehouse Design—As with everything else in life, a structure has dimensions that make it less than ideal.

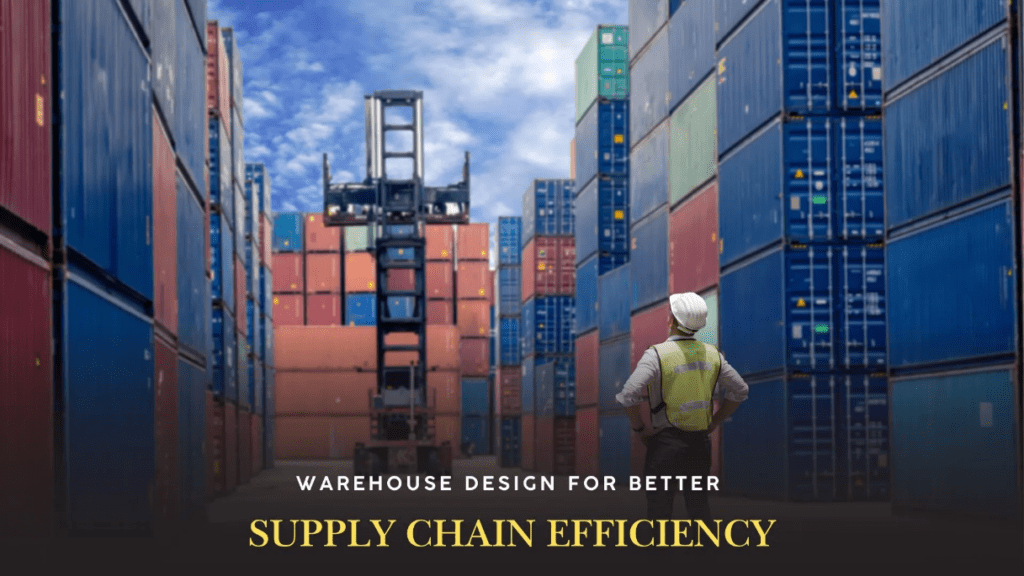

Core Principles of Warehouse Design

A high-performing warehouse begins with a good design. These are the crucial bricks making up your Facility, either a new build or optimizing an existing one.

1. Streamlined Layouts for Seamless Functioning

Having a wisely laid-out layout minimizes unnecessary movement and saves time and effort. Popular layouts include:

U-shape Flow: Ideal for receiving, holding, and shipping, optimizing space and workflow.

Linear Layouts: Best suited for high-volume operations where minimizing cross-traffic is essential.

L-shaped Layouts: Perfect for handling various product ranges or flows, offering flexibility in design.

2. Efficient Storage Systems

Opt for storage solutions that align with your inventory and operational requirements:

For bulk storage, pallet racking systems:

Dynamic shelving: Providing access to fast-moving products

Automated Systems: To ensure accuracy and speed of handling.

3. Technology Integration

Modern tools like warehouse management systems (WMS) and RFID technology are game-changers for managing inventory and improving order accuracy.

4. Scalability for Future Growth

Design your warehouse with flexibility in mind. A scalable layout ensures your facility adapts to evolving business needs.

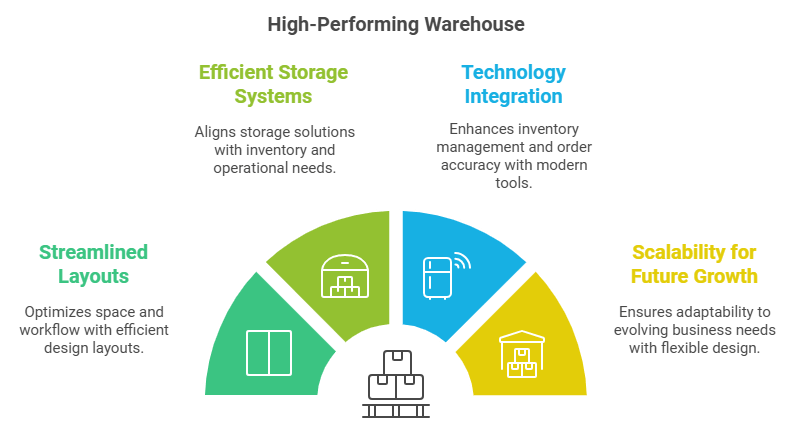

The Financial Impact of a Well-Designed Warehouse

A well-designed warehouse can dramatically improve your operations and impact your bottom line. Here are the top five financial benefits:

1. Reduced Operating Costs

Efficient layouts and streamlined workflows cut down on unnecessary labor, equipment usage, and energy consumption. Businesses save significantly on operational expenses by optimizing material flow and reducing redundant processes.

2. Maximized Space Utilization

Smart warehouse designs make the most of every square foot. Utilizing vertical storage, compact shelving, and strategic layouts allows businesses to store more products without the need for costly expansions or additional facilities.

3. Faster Order Fulfillment

An organized warehouse improves picking and packing efficiency, leading to quicker order processing. Faster fulfillment enhances customer satisfaction, reduces shipping delays, and lowers costs associated with returns or complaints.

4. Improved Inventory Accuracy

Modern inventory management tools, integrated into a well-designed warehouse, minimize errors and reduce losses from misplaced or excess stock. Accurate tracking also prevents overstocking or stockouts, saving money and ensuring smooth operations.

5. Scalability for Future Growth

A well-thought-out warehouse is built to adapt to future needs. Scalable designs prevent costly relocations or overhauls, enabling businesses to expand operations seamlessly without significant upfront investment.

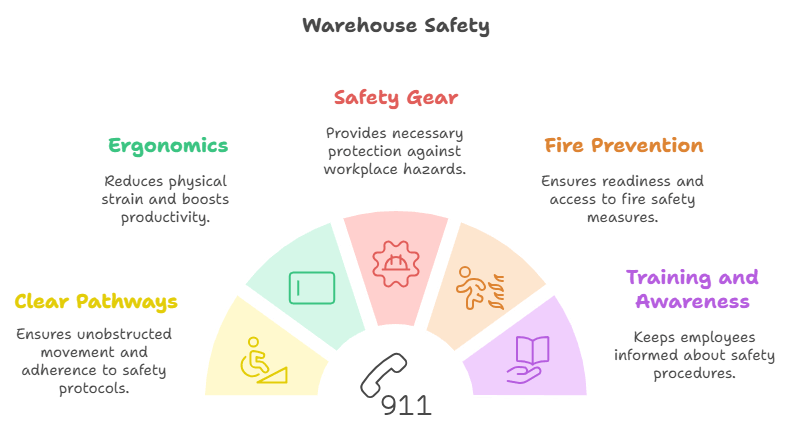

Safety First: Creating a Secure and Productive Environment

Safety is important when it comes to both keeping the employees safe and making sure everything goes smoothly in a warehouse. The lack of accidents, downtime, and the productive environment created by a safe haven contribute to the above. Some of the essentials when it comes to warehouse safety are:

Clear Pathways and Proper Signage: Ensure that aisles and pathways are wide, clear of obstructions, and marked to prevent accidents. Proper signage and labeling also help in guiding staff efficiently and ensuring that safety protocols are followed.

Ergonomics: Create workspaces that reduce the physical strain on employees — adjust shelving, and acquire lifting equipment. It minimizes the risk of injuries but also boosts long-term productivity.

Safety Gear: Add safety equipment as required like guardrails, anti-slip floors, and safety barriers around the machine. Frequent examination of devices and handing out unique protection equipment including helmets, gloves, and characteristic jackets that are worn on the body with the help of workers.

Fire Prevention and Emergency Measures: Make sure fire exits are not blocked off, and that there is an easily accessible method to access any fire safety equipment. Schedule regular safety drills for all employees to familiarize them with the emergency procedures

Training and Awareness: Consistent safety training ensures employees are familiar with procedures, safety standards, and how to respond in the event of an emergency.

A well-designed, safe warehouse reduces the risk of accidents, enhances morale, and improves overall efficiency, lowering insurance costs and minimizing costly downtime.

Start Your Warehouse Transformation with 7th Mile Shift

At 7th Mile Shift, we specialize in creating customized solutions that elevate your supply chain. From optimized layouts to advanced technology integration, we help businesses achieve peak operational performance.

Ready to turn your warehouse into a competitive advantage?

Contact 7th Mile Shift today and start your journey to success!

Read More: Inventory Management Tips: Optimize Order Quantity & Stock