5 Ways to Optimize Your Warehouse Management Systems

Managing a warehouse efficiently is a complex task. Between tracking inventory, fulfilling orders, and ensuring smooth operations, a lot can go wrong.

An optimized Warehouse Management System (WMS) can transform these challenges into opportunities for increased productivity and profitability.

Here, we’ll explore five strategies to enhance your WMS, drawing inspiration from tried-and-tested industry practices.

Invest in Advanced Inventory Management Software for Warehouse Management Systems

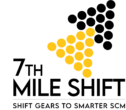

A robust Warehouse Management System begins with inventory management software that provides real-time insights into stock levels and movement.

Gone are the days of manual inventory tracking, which is prone to errors and inefficiencies. Advanced systems can:

- Track stock levels in real-time

- Automate reordering to prevent stockouts

- Integrate seamlessly with other systems, such as ERP and CRM platforms

For example, businesses that implement these tools often experience reduced inventory discrepancies and improved order accuracy.

Start by evaluating your current Warehouse Management System’s capabilities and look for software that aligns with your operational needs.

Optimize Your Warehouse Layout to Improve Warehouse Management Systems

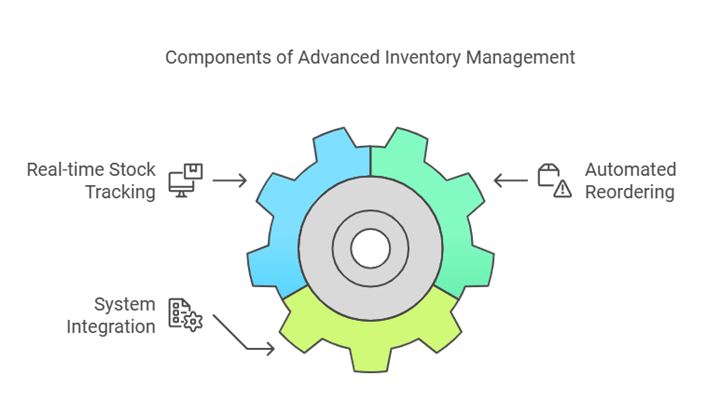

Your warehouse layout directly impacts the efficiency of order fulfillment. A poorly organized space can lead to wasted time and energy.

Instead, consider the following layout optimization tips:

- Group High-Demand Items: Place frequently picked items closer to the packing and shipping areas.

- Streamline Pathways: Ensure aisles are wide enough for equipment but not so expansive that they waste space.

- Implement Labeling Systems: Use clear signage and barcoding to guide employees quickly to the right location.

A periodic review of your warehouse layout ensures that your Warehouse Management Systems remain efficient as your business grows or product lines change.

Automate Repetitive Tasks in Warehouse Management Systems

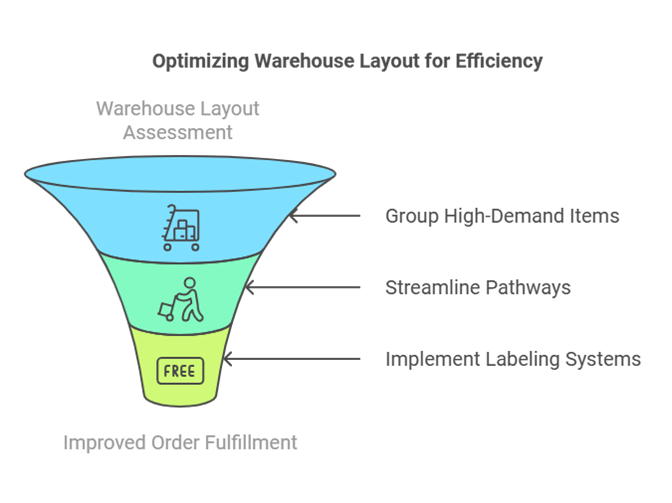

Automation is no longer a luxury—it’s a necessity. Automated systems can handle repetitive and time-consuming tasks, freeing up your workforce for more strategic responsibilities.

Consider implementing:

- Automated Storage and Retrieval Systems (AS/RS): These systems speed up the picking process by retrieving items automatically.

- Conveyor Belts and Sortation Systems: Streamline the movement of goods within the warehouse.

- Robotics: Use robotic systems for picking, packing, or palletizing.

By integrating automation into your Warehouse Management Systems, you reduce human error, enhance speed, and lower operational costs.

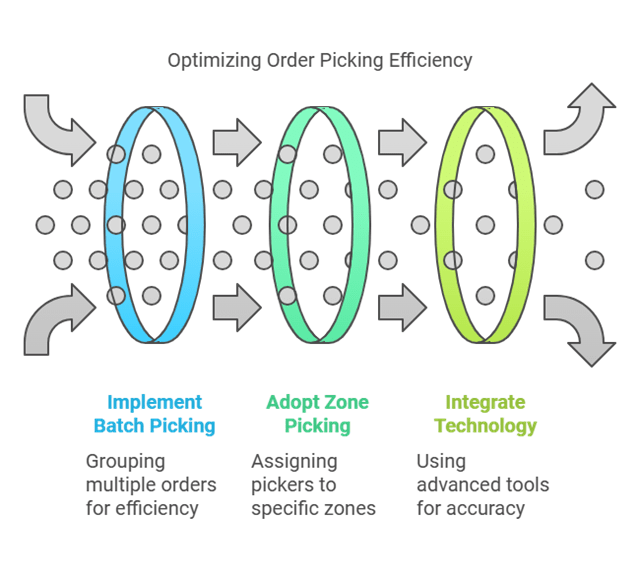

Enhance Order Picking Processes with Warehouse Management Systems

Order picking is one of the most labor-intensive activities in a warehouse. Improving this process can lead to significant time and cost savings.

Here’s how you can optimize order picking:

- Batch Picking: Group multiple orders to pick items more efficiently.

- Zone Picking: Assign pickers to specific zones to minimize travel time.

- Technology Integration: Tools like pick-to-light systems and voice-directed picking can enhance accuracy and speed.

Regularly reviewing your order-picking methods ensures they align with your Warehouse Management Systems’ operational demands and customer expectations.

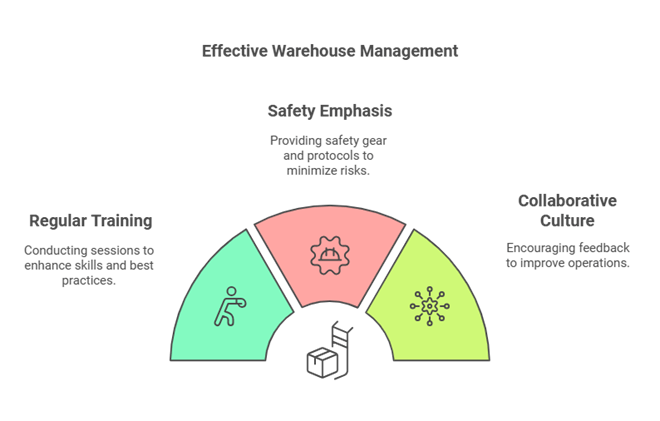

Prioritize Employee Training and Safety for Effective Warehouse Management Systems

Your employees are your most valuable asset. A well-trained team not only improves operational efficiency but also reduces workplace accidents.

Here’s how to ensure your workforce is equipped for success:

- Provide Regular Training: Conduct sessions on using Warehouse Management Systems tools and implementing best practices.

- Emphasize Safety: Equip employees with the necessary safety gear and implement protocols to reduce risks.

- Foster a Collaborative Culture: Encourage employees to share feedback on warehouse operations to identify potential areas for improvement.

A safe and knowledgeable workforce contributes to a more productive and resilient warehouse environment.

Final Thoughts on Optimizing Warehouse Management Systems

Optimizing your Warehouse Management Systems is not a one-time effort—it’s an ongoing process.

By investing in advanced technologies, refining operational workflows, and prioritizing employee engagement, you can create a system that supports your business’s long-term success.

Remember, the goal isn’t just to keep up with the competition but to set a benchmark for efficiency and innovation in warehouse management.

Start implementing these strategies today, and watch your Warehouse Management Systems transform for the better.

Take the Next Step with 7th Mile Shift

Ready to elevate your warehouse operations to the next level? At 7th Mile Shift, we specialize in optimizing Warehouse Management Systems tailored to your business needs.

Let our experts guide you through cutting-edge solutions that enhance efficiency and drive growth.

Contact us today to learn how we can help your business achieve seamless warehouse management and unparalleled success!

Read More: Effective Logistics Management: Best Practices for 2025