Transforming Supply Chains: System Designs for the Modern Era

Transforming Supply Chains: Are you struggling with supply chain disruptions? In today’s volatile global landscape, constant changes and unexpected challenges are the norm.

From geopolitical instability to fluctuating consumer demand, businesses face unprecedented pressures.

Simply surviving isn’t enough – competitive advantage now hinges on fundamentally rethinking and redesigning your supply chain systems.

This post moves beyond buzzwords to explore the crucial aspects of supply chain transformation, focusing on foundational system designs that foster agility, resilience, and efficiency.

This blog post will highlight the important aspects of Supply Chain Transformation toward preferred foundational system designs that help to improve agility, resilience, and efficiency in processes.

The Imperative for Transformation

Traditional, linear supply chain models are no longer adequate for today’s complex environment. Organizations are actively engaged in transformation due to:

- Increased Volatility & Uncertainty: Geopolitical events, natural disasters, and crises require highly responsive supply chains.

- Evolving Customer Expectations: Customers demand speed, transparency, and personalized experiences.

- Technological Advancements: AI, IoT, and cloud computing offer unprecedented opportunities for optimization and automation.

- Sustainability Concerns: Growing pressures to reduce ecological impact necessitate radical changes in supply chain structures and strategies.

- Data Overload: Companies are drowning in data but struggle to extract relevant information for decision-making.

What Does Transforming Supply Chains Mean?

Supply chain transformation is more than just digitizing existing processes. It requires a complete overhaul of end-to-end operations, focusing on:

- Enhanced Visibility & Transparency: Real-time insights into every stage of the supply chain, from sourcing to delivery. This includes tracking inventory, monitoring supplier performance, and identifying potential disruptions proactively.

- Increased Agility & Responsiveness: Building systems that rapidly adapt to changing market conditions and customer demands. This necessitates flexible sourcing, dynamic planning, and the ability to quickly reconfigure operations.

- Improved Resilience & Risk Management: Designing supply chains to withstand and quickly recover from disruptions. This includes diversifying sources, developing contingency plans, and leveraging data for proactive risk assessment.

- Data-driven decision-making: Utilizing big data analytics to optimize processes, improve demand forecasting, enhance accuracy, and identify cost-saving opportunities.

- Collaboration & Connectivity: Enabling seamless communication and information sharing across the entire supply chain ecosystem, including suppliers, manufacturers, distributors, and customers.

- Integration of Sustainability: Incorporating ethical sourcing, responsible manufacturing, efficient logistics, and circular economy principles.

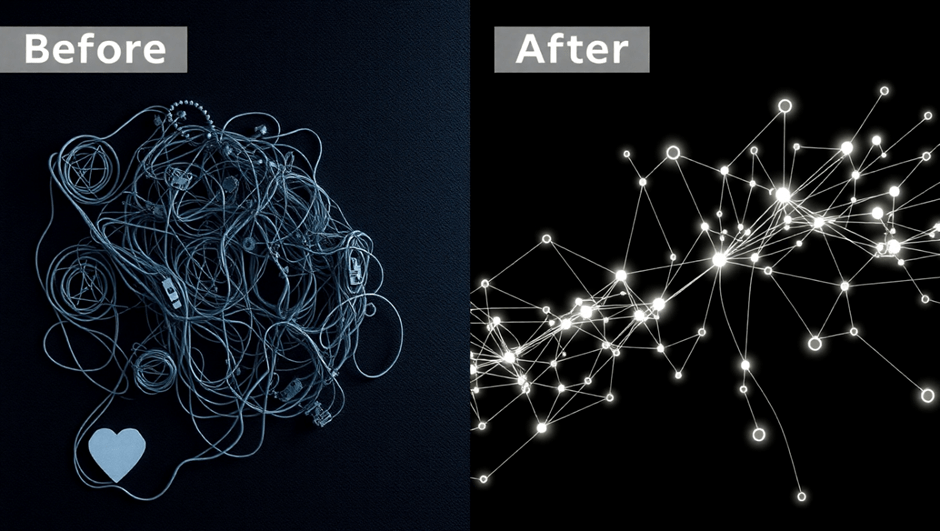

Key System Designs for the Modern Era

Successful supply chain transformation relies on specific system designs that address foundational challenges and opportunities. Essential elements include:

- Digital Twins: Creating virtual models of the supply chain for simulation, testing, and optimization without disrupting real-world operations. This enables proactive risk management and data-driven decision-making.

- AI-Powered Planning & Forecasting: Utilizing AI and machine learning to analyze vast data sets for more accurate demand forecasting, enabling optimal inventory levels, reduced waste, and improved customer service.

- Connected & Autonomous Operations: Leveraging IoT sensors and automation technologies for real-time monitoring of asset movements, equipment performance, and the automation of routine tasks. This increases efficiency, minimizes errors, and improves visibility.

- Cloud-Based Collaboration Platforms: Utilizing secure, scalable cloud platforms to facilitate seamless communication and information sharing across all stakeholders. This enhances transparency, strengthens partnerships, and accelerates decision-making.

- Flexible & Modular Architectures: Designing supply chain systems with modular components that allow for easy adaptation and reconfiguration to meet changing business needs. This fosters agility and reduces dependence on rigid, monolithic structures.

- Advanced Analytics & Reporting: Implementing powerful analytical tools to extract actionable insights from supply chain data, enabling performance monitoring, identification of bottlenecks, and continuous improvement efforts.

- Robust Cybersecurity Measures: Implementing strong security protocols, including authentication and encryption, alongside regular security audits to protect sensitive supply chain data from cyber threats.

Embarking on Your Transformation Journey

Supply chain transformation is not a one-size-fits-all solution. It requires a tailored strategy and a phased approach aligned with your organization’s specific needs and objectives. Key steps include:

- Define a Clear Vision and Strategy: Set specific goals for the transformation and develop a roadmap to achieve them.

- Assess Current State: Evaluate the effectiveness of existing supply chain processes and identify areas for improvement.

- Prioritize Improvement Areas: Focus on initiatives that will have the greatest impact on strategic goals.

- Select Appropriate Technologies: Choose and implement technologies that align with your specific needs and budget.

- Invest in Training & Development: Ensure your team has the skills and knowledge to operate and manage the new systems effectively.

- Foster a Culture of Innovation: Create an environment that encourages continuous experimentation and improvement.

Conclusion

The era of predictable supply chains is over. Transformation is no longer optional but essential for organizations seeking to thrive in today’s dynamic environment.

By embracing new system designs and a strategic approach, you can build supply chains that are more resilient, agile, and efficient, leading to increased customer satisfaction and sustainable growth.

Are you ready to unlock the full potential of your supply chain?

Transforming your supply chain can seem daunting, but with the right guidance, it can be a seamless and rewarding process. Don’t let outdated systems hold your business back.

Contact 7th Mile Shift today for a consultation and discover how we can help you achieve supply chain excellence.

Let us be your partner in navigating this complex landscape and building a resilient, agile, and efficient supply chain tailored to your unique needs.

FAQ

- What are the 5 stages of SCM?

The five stages of SCM are planning, sourcing, manufacturing, delivery, and returns. - How is technology transforming the supply chain?

Technology transforms supply chains through real-time tracking, AI-driven insights, automation, and enhanced transparency. - What does change in the supply chain mean?

Change in the supply chain refers to adapting processes and strategies to meet evolving demands and market conditions. - What is a supply chain?

A supply chain is a network of processes and entities involved in producing and delivering a product or service. - What is the supply chain process?

The supply chain process involves sourcing, production, logistics, inventory management, and customer service.

Read More: Warehouse Design and Layout in 2025: Future Strategies