How Supply Chain Optimization Can Lead to Cost Savings

Supply Chain Optimization: There is a lot of competition in the business today. Business sustainability and profitability are assured only by controlling and managing costs. Properly regulating the supply chain is the most important way to do this.

When the supply chain works properly, business operations run efficiently. From purchasing the product to delivering it to the end customer, every stage of the supply chain will result in significant cost reductions.

Companies like 7th Mile Shift have demonstrated how strategic supply chain solutions can yield tangible financial benefits. In this article, we have researched how proper supply chain management can reduce costs.

We have also given real examples of how we have reduced costs through the services of 7th Mile Shift.

Understanding Supply Chain Optimization

As the supply chain is streamlined, all goods come and go efficiently and effectively. Use modern methods, tools, and technologies for this. The aim is to use resources efficiently, reduce wastage, and make things run smoothly.

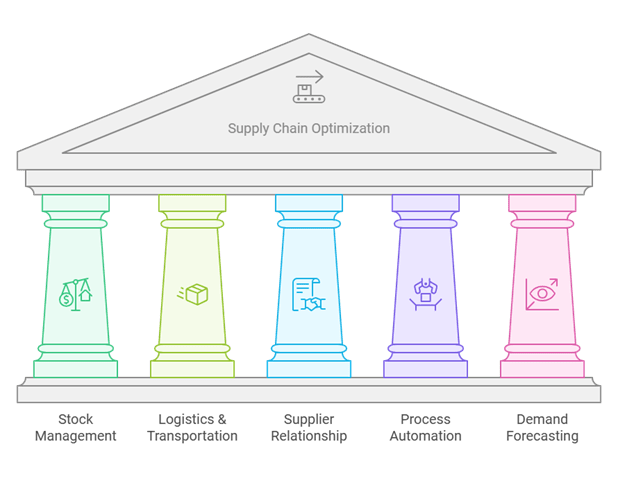

Optimization typically focuses on several key areas, including:

- Stock Management: It should be ensured that there is enough stock and not too much stock.

- Logistics & Transportation: Properly planning the route of goods and delivery schedule to reduce energy and transport costs.

- Supplier Relationship: Negotiate good terms with the suppliers and achieve cost savings product purchases.

- Process Automation: Use technologies to reduce manual work and avoid errors.

- Demand forecasting: Data analysis of customer needs and supply of appropriate products.

Cost Savings Opportunities in Supply Chain Optimization.

1. Reduced Inventory Costs

Stock management is very important to reduce costs. Excess inventory can lead to restricted cash flow, handling, and storage costs to increase. If there is less stock, the sales will go down and the customers will go away. By using advanced analysis and stock management systems, stocking can be done properly.

For example, many companies have reduced store costs by up to 20% using 7th Mile Shift’s stock management strategies. By analyzing consumption trends, forecasting future requirements, maintaining optimal stock levels, and minimizing excess, they have achieved significant cost savings.

2. Lower Transportation Expenses

Transportation and logistics costs are large costs in the supply chain. If you plan the route of the goods properly, send several small deliveries together, and monitor the movement of the vehicles using digital tools, you can reduce costs a lot.

A mid-size e-commerce retailer reduced transportation costs by up to 25% after getting route planning right.

Deliveries can be combined and sent together, following fuel-efficient routes to minimize environmental impact.

- Enhanced Supplier Negotiations

The supply chain can be regulated properly by establishing good relations with suppliers and making a model contract that does not affect both parties. You can analyze the data, negotiate a good price, buy a good time for payment, and ensure the smooth, frequent arrival of goods.

7th Mile Shift delivered a supplier relationship management program to a manufacturing company, by which they could reduce the cost of purchasing products by 15%.

They streamlined operations by contracting for bulk purchases, negotiating effectively with suppliers, and reducing lead times.

- Minimized Operational Waste

In lean practices, adding automation can reduce unnecessary costs and streamline how things are done. It reduces unnecessary work, prevents work from stopping, and makes regular work to be done by machine, which can reduce costs.

For example, 7th Mile Shift helped a manufacturing company to design and implement automated thru warehouse management system (WMS). This enabled the manufacturer to streamline how things were picked and placed, reducing errors and labor costs by up to 23%.

- Improved Demand Forecasting

For the supply chain to work properly, demand forecasting is very important. Using data analysis and machine learning to accurately predict how many products customers will buy, overproduction and stock shortages can be prevented.

Using 7th Mile Shift’s demand forecasting solutions, a retail company has increased forecasting accuracy by 25%.

Due to that the unsold stock has been reduced by 10% and the loss due to selling at a discount has also been reduced.

Key Takeaways for Businesses

The examples above illustrate that supply chain optimization is not just a theoretical concept but a practical strategy with measurable financial benefits.

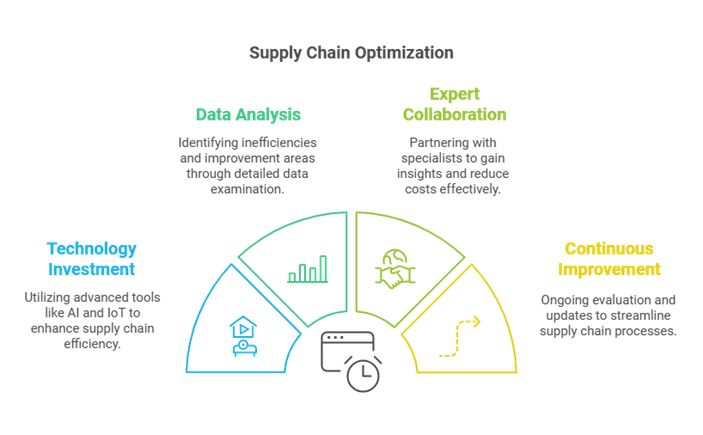

Here are some key takeaways for businesses looking to optimize their supply chains:

- Invest in technology: Use tools like AI, machine learning, and IoT to revolutionize the supply chain. It helps a lot in making the right decisions and controlling costs.

- Leverage data: By examining the data, you will know where there are inefficiencies and where you can improve.

- Work with experts: Work with experts like 7th Mile Shift to get the knowledge and tools you need to reduce costs.

- Continuous Improvement: Streamlining the supply chain should not be a one-time thing. Keep evaluating and keep updating.

Conclusion

Properly orchestrating the supply chain can reduce costs and streamline how things are done. If you pay attention to important things like stock management, logistics, supplier relationship, and demand for cost, you can reduce a lot of costs.

7th Mile Shift has many examples of how customers have streamlined their supply chain and reduced costs. In this highly competitive business world, it is essential to manage the supply chain properly to run the business profitably.

Read More: Strategic Sourcing: The Key to Supply Chain Success